Transforming Modern Production with Smart Deburring Solutions

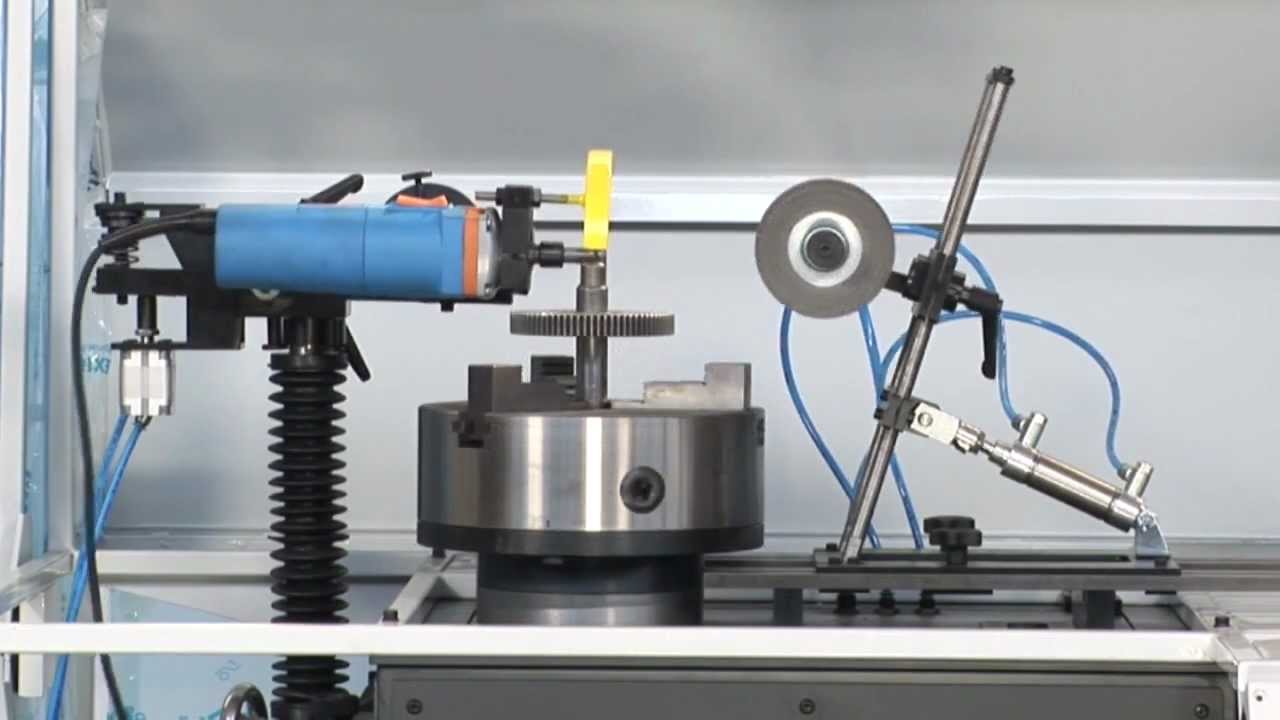

As global industries strive for flawless production and reduced human error, the demand for smarter machinery continues to rise. The AUTOMATIC DEBURRING MACHINE stands at the forefront of this evolution, redefining how manufacturers handle edge finishing, surface refinement, and part preparation. Integrated with intelligent control systems, this advanced machinery offers unmatched consistency, speed, and adaptability across various production lines.

Optimized Edge Finishing with Smart Integration

One of the key challenges in modern fabrication is ensuring that components are burr-free without compromising their structural integrity. The AUTOMATIC DEBURRING MACHINE addresses this by incorporating sensor-based control, adaptive pressure settings, and programmable cycles. This level of automation allows manufacturers to process large volumes of parts with consistent quality, whether they are working with aluminum, stainless steel, or exotic alloys.

By integrating intelligent systems, the machine can detect irregularities in part geometry, adjust parameters automatically, and deliver precision finishing without manual adjustments. This results in significant time savings, improved workflow, and reduced rework.

Enhancing Productivity in High-Demand Environments

Efficiency is a defining factor for competitiveness. With the AUTOMATIC DEBURRING MACHINE, factories can maintain high throughput while ensuring that every component meets strict quality benchmarks. These machines run continuously with minimal supervision, optimizing production cycles and eliminating delays caused by manual deburring.

Thanks to their intelligent software interfaces, operators can quickly switch between part programs, monitor real-time performance data, and minimize downtime. The seamless integration with conveyor systems and robotic arms further enhances the automation potential, making this solution essential for large-scale, uninterrupted operations.

Trusted Across Precision-Driven Sectors

The AUTOMATIC DEBURRING MACHINE is widely embraced by industries such as aerospace, medical, electronics, and automotive, where tolerance levels are narrow and finishing quality is paramount. Its ability to manage complex contours and delicate parts with precision makes it suitable for both rigid and fragile materials.

Manufacturers rely on this technology not only for its speed but for its repeatability. Regardless of batch size or part complexity, the machine ensures uniform surface conditions, helping businesses maintain ISO and other international certifications.

Smart Engineering for Next-Level Performance

Modern engineering requirements demand machines that are both adaptive and data-driven. The AUTOMATIC DEBURRING MACHINE excels with intelligent control systems that enable real-time diagnostics, predictive maintenance alerts, and performance analytics. These capabilities reduce unscheduled downtime, extend machine life, and ensure continuous improvement in production efficiency.

The integration of AI-assisted features and IoT connectivity allows supervisors to track productivity remotely, make data-backed decisions, and fine-tune operations for specific part requirements. This digital capability places the machine at the heart of Industry 4.0 strategies, helping manufacturers future-proof their investments.

Sustainable Manufacturing with Intelligent Deburring

Environmental responsibility is a growing concern across industries. The AUTOMATIC DEBURRING MACHINE supports sustainable practices by reducing energy usage, minimizing material wastage, and eliminating the need for consumables used in manual processes. Its intelligent systems ensure that only the necessary force and time are applied for each component, conserving resources without compromising output.

Furthermore, closed-loop systems and built-in filtration ensure minimal environmental impact, making this solution a smart choice for companies aligned with green manufacturing initiatives.

Precision, Power, and Control in One Machine

Unlike traditional machines that rely on fixed settings, the AUTOMATIC DEBURRING MACHINE provides manufacturers with full control over deburring parameters. Operators can customize brush pressure, rotation speed, and dwell time through a user-friendly control panel. This flexibility enables it to handle a wide range of components without switching machines or retooling, streamlining the production process.

These intelligent adjustments reduce operator fatigue and eliminate inconsistencies that often arise from manual labor. With unmatched control and precision, this machinery elevates overall product quality and enhances customer satisfaction.

Conclusion: The Intelligent Path to Flawless Manufacturing

The AUTOMATIC DEBURRING MACHINE with intelligent control systems is a breakthrough for manufacturers aiming for perfection, efficiency, and adaptability. Its ability to automate edge finishing with real-time data and smart diagnostics positions it as a cornerstone of advanced manufacturing setups. With a global reputation for reliability, this machine empowers industries to meet the growing demands for precision parts while minimizing costs and maximizing output. Investing in this intelligent solution is not just about better finishing—it’s about transforming how manufacturing is done.