Introduction

Hydraulic systems are the backbone of many industries, from construction and manufacturing to agriculture and mining. These systems power heavy machinery, enabling them to operate efficiently and reliably under demanding conditions. However, without proper hydraulic system maintenance, equipment can break down prematurely, leading to costly repairs and downtime. At RHK Hydraulic Cylinder Services Inc, we specialize in helping businesses extend the life of their machinery through comprehensive hydraulic system maintenance programs that focus on prevention, performance, and long-term cost savings.

Why Hydraulic System Maintenance is Critical

A well-designed hydraulic system maintenance program is essential for keeping machines running at peak efficiency. Hydraulic systems are subject to intense pressure, high temperatures, and constant wear. If routine hydraulic system maintenance is neglected, small issues like fluid contamination, leaks, or worn seals can escalate into major failures. Regular hydraulic system maintenance not only prevents breakdowns but also maximizes productivity, improves safety, and lowers the total cost of ownership for your equipment.

Key Elements of a Hydraulic System Maintenance Program

An effective hydraulic system maintenance program includes several core components:

1. Fluid Management

Hydraulic fluid is the lifeblood of your system. Regular hydraulic system maintenance ensures that fluids are kept clean, at the proper level, and within the correct temperature range. Contaminated or degraded fluid can damage pumps, valves, and cylinders. Scheduled fluid analysis is a vital part of hydraulic system maintenance that helps detect early warning signs of wear.

2. Leak Detection and Repair

Leaks are one of the most common problems in hydraulic equipment. A proactive hydraulic system maintenance program identifies leaks early and addresses them before they cause performance issues or safety hazards. By focusing on seal integrity and hose inspections, hydraulic system maintenance minimizes fluid loss and prevents system inefficiency.

3. Component Inspections

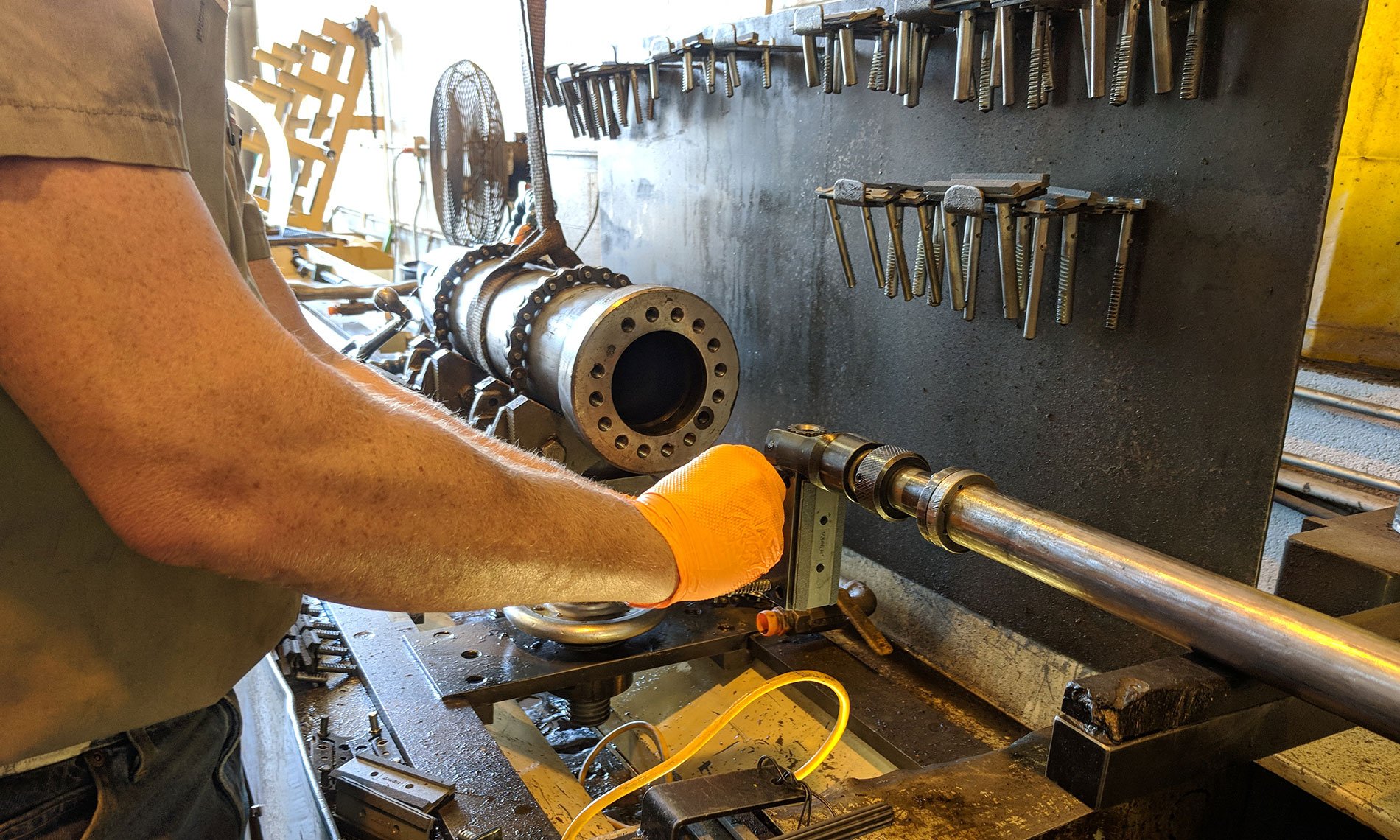

Regular inspections are crucial for identifying worn or failing parts. As part of hydraulic system maintenance, cylinders, pumps, valves, and hoses are checked to ensure they meet operational standards. Replacing components before they fail extends equipment life and reduces the risk of catastrophic breakdowns.

4. Preventive Scheduling

The best hydraulic system maintenance is preventive, not reactive. Establishing a routine schedule ensures that critical checks and services are performed consistently. By incorporating preventive strategies, hydraulic system maintenance reduces unscheduled downtime and enhances overall machine performance.

Benefits of Hydraulic System Maintenance

When businesses commit to a structured hydraulic system maintenance program, the benefits are substantial. Improved efficiency, lower repair costs, and reduced downtime are just the beginning. Proper hydraulic system maintenance also helps companies comply with safety standards and reduces the environmental impact of fluid leaks and waste. For industries that rely on heavy-duty machinery, hydraulic system maintenance is not an expense but an investment in long-term reliability.

How RHK Hydraulic Cylinder Services Inc Can Help

At RHK Hydraulic Cylinder Services Inc, we provide tailored hydraulic system maintenance programs designed to meet the specific needs of your equipment. Our team of experts offers advanced diagnostic tools, skilled technicians, and industry-leading solutions to keep your systems running at their best. Whether you need routine fluid testing, emergency repairs, or complete system overhauls, our comprehensive approach to hydraulic system maintenance ensures maximum uptime and extended equipment life.

Conclusion

In today’s demanding industries, equipment downtime is not an option. Implementing a reliable hydraulic system maintenance program is the key to ensuring performance, safety, and longevity. At RHK Hydraulic Cylinder Services Inc, our expertise in hydraulic system maintenance helps businesses save money, prevent costly failures, and keep machinery operating at peak performance. By prioritizing hydraulic system maintenance, you are investing in the future of your equipment, your productivity, and your bottom line.